Recently, the technical service personnel of Wuhan HV HIPOT Electric Co., Ltd. (hereinafter referred to as “HV HIPOT”) traveled to Hong Kong to complete the in-depth maintenance inspection and customized product training services for the long-term cooperation client regarding the GDYT-60kW non-discharge induction withstand voltage test device. From equipment performance calibration to empowerment of operation and maintenance skills, HV HIPOT adopted a “technology + service” dual-driven model to continuously ensure the stable operation of power testing equipment in Hong Kong, and with professional strength, deepened the cross-border cooperation ties.

Precise Maintenance: Building a Defense Line for Long-Term Stable Equipment Operation

As a core device in the field of power testing, the regular maintenance of the no-discharge test device is crucial for ensuring testing accuracy and operational safety. Considering the environmental characteristics of Hong Kong, which has high temperatures and humidity, as well as the actual demand for customers’ equipment to operate under high load for a long time, the technical team of HV HIPOT has carried out comprehensive maintenance and inspection services in all dimensions:

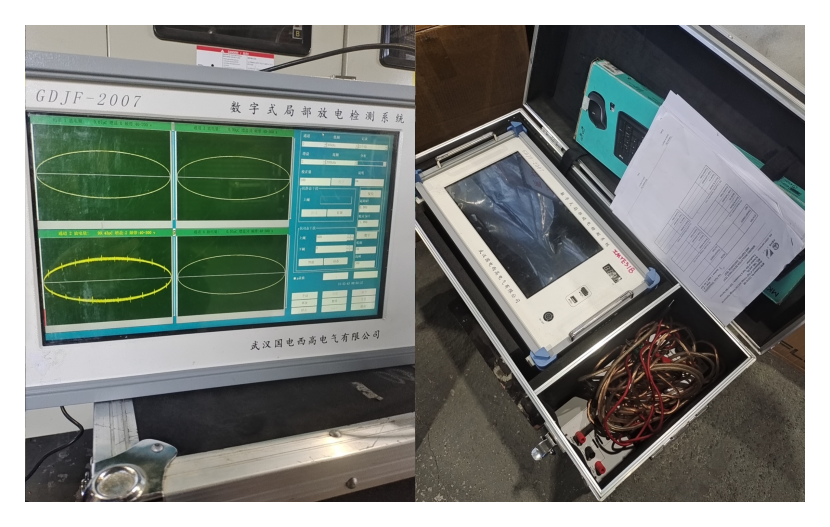

Deep performance calibration: Using certified standard calibration equipment, the device’s local discharge quantity, test voltage stability, and other core indicators are precisely calibrated to ensure a high-precision standard of local discharge quantity ≤ 5 pC and voltage fluctuation ± 0.5%, fully meeting the requirements of the Hong Kong “Electricity (Lines) Regulations”;

Comprehensive condition inspection: Key components such as the electromagnetic interference protection module and abnormal discharge warning system are carefully inspected, core components are cleaned of dust and impurities, connection nodes are tightened, and aging and easily-damaged parts are replaced, avoiding equipment failure risks from the source;

Environmental adaptation optimization: Considering the limited space layout of the Hong Kong laboratory, the equipment’s heat dissipation structure and wiring method are optimized to enhance the equipment’s adaptability to high-temperature and high-humidity environments, and extend its service life.

Customized Training: Empowering Customers to Master the Full Process of Maintenance Skills

To enable the customer team to fully master the operation, maintenance, and fault handling capabilities of the equipment, HV HIPOT has developed a three-in-one bilingual training system of “theory + practical operation + case study”:

Theoretical explanation: Systematically explaining the working principle of the no-discharge test device, core parameter interpretation, and key points of daily maintenance and care, combined with the equipment detection scenarios in the Hong Kong power grid, focusing on analyzing common interference sources and elimination methods in local discharge detection;

Practical operation: Guiding practical operations on the customer’s laboratory site, covering the entire process of equipment startup self-check, parameter setting, sample testing, data export, etc., teaching equipment calibration and simple fault troubleshooting skills step by step;

Case analysis: Sharing domestic and foreign similar equipment operation cases, including equipment protection in high-temperature and high-humidity environments, and responses to performance degradation after long-term operation, providing practical experience to help the customer team quickly solve actual problems.

Post time: Jan-30-2026