OEM Best megger test electrical Supplier – Substation Temperature Monitoring System – HV Hipot

OEM Best megger test electrical Supplier – Substation Temperature Monitoring System – HV Hipot Detail:

General Information

There are usually two ways to monitor the insulation condition of high voltage electrical equipment in substations: online monitoring and live (portable) online detection. The former one can obtain the characteristic parameters reflecting the abnormal insulation of the equipment at any time, which is convenient for automatic management. However, the investment is relatively large, the installation and construction are relatively troublesome, and regular maintenance is needed. For the latter, it has the advantages of low investment, highly targeted, easy to install, maintain and update. As long as the sampling unit is installed in the electrical equipment in advance, a regular detection can be done for electrical equipment in operation, and insulation flaw can be found in time, so as to prolong the pretest period of power failure and completely replace on-line monitoring method.

GDDJ-HVC dielectric loss tester for live capacitive equipment can be used to measure dielectric loss and capacitance of capacitive equipment (bushing, CT, CVT, coupling capacitor), and detect insulation flaws effectively.

Features

1. External hole type current sensor with high precision is often used instead of the traditional sampling unit, which includes more than one switch circuit. During testing, multiple short tabs are needed to lead end shielding current to test instrument. GDDJ – HVC uses traditional straight-through structure, can be installed near the equipment, lead of end shielding is not broken and the length is very short, which avoid open circuit of end shielding. The sensor can accurately detect signals within 100μA~700mA. Impedance of sensor is low, can withstand power frequency current 10A and lightning impulse current 10kA, meet use conditions of online detection.

2. The sampling unit adopts die-casting aluminum shell sealing waterproof design, and adopts waterproof cable connector for secondary output, which is convenient for connection; After the sensor is installed, it is normally not energized. For testing, only the secondary cable of the sampling unit need be connected, and “plug and play” can be achieved without any operation on the end shielding signal cable.

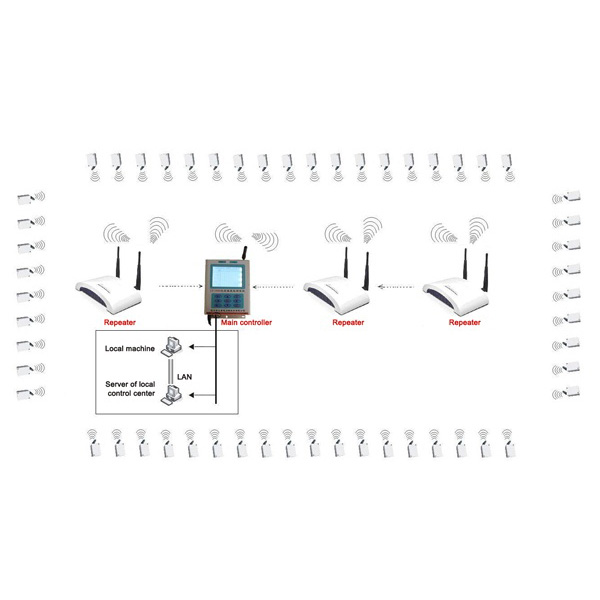

3. The core processor of the instrument is American TI 32-bit floating-point high performance digital signal processor (DSP), which runs a real-time operating system and adopts an extended 16-bit, high-speed, multi-channel synchronous sampling analog digital converter (A/D) to realize real-time measurement and high-precision calculation of the monitored quantity. Able to monitor multiple devices simultaneously.

4. Two on-line detection methods for dielectric loss can be provided, which can measure dielectric loss difference and capacitance ratio of two capacitive devices in the same phase, and PT secondary voltage can be used as the reference signal to measure the capacitance and dielectric loss of the device. Using the compensating current sensor and advanced digital filtering technology, the problem of dielectric loss precision and stability is solved, combined with perfect electromagnetic shielding measures and advanced processing technology, digital filtering can ensure dielectric loss test results are not affected by the influence of harmonic interference and pulse interference, with absolute precision up to ±0.05%.

5. With the detection of dielectric loss difference and capacitance ratio of in-phase capacitive equipment, it can not only avoid the distortion of dielectric loss test result caused by using PT secondary voltage as the reference signal, but also help to reduce the influence of phase-to-phase electric field interference.

6. The detector is equipped with a large LCD screen for displaying the monitored voltage, current, dielectric loss, resistive current, capacitive current and other data.

7. The tester not only has the function of live detection, but also can monitor the equipment online for a long time, and automatically record the monitored data.

8. The system adopts external sensors instead of “traditional sampling unit”, which can be easily upgraded from “live detection” to “online monitoring” under normal operation of the equipment. There is no need to remove the installed sensors, no need to disable the device, just add a monitoring unit (IED).

9. The detector adopts portable design, simple to operate, the lithium battery in the machine can maintain 8 hours of continuous working time, fully meet the requirements of field use.

Specification

| Main unit | |

| Power supply | Maintenance-free battery |

| Cable | 30m, 2 pieces |

| Ambient temperature | -45~60℃ |

| Display | Large screen LCD display, suitable for outdoor use. |

| Size | 430*340*160mm |

| Weight | 5kg |

| Measurement range & accuracy | |

| Current | Cx=100μA~1000mA, Cn=100μA~1000mAAccuracy: ±(0.5%+1digit) |

| Voltage | Vn=3V~300V Accuracy: ±(0.5%+1 digit) |

| Dielectric loss | Tanδ= -200%~200% Accuracy: ±0.05% |

| Capacitance ratio | Cx: Cn=1:1000~1000:1 Accuracy: ±(0.5%C+1 digit) |

| Capacitance |

Cx=10pF~0.3μF Accuracy: ±(0.5%C+2pF) Note: actual measurement accuracy is related with current of test object and accuracy of PT (or CVT) in use. |

| Resistive current | Irp=10μA~200mA (peak) Accuracy: ±(0.5%+1digit) |

| Capacitive current | Icp=10μA~200mA Accuracy: ±(0.5%+1digit) |

| Other characteristics | |

| Harmonic suppression | Waveform distortion of input current signal will not affect the measurement accuracy. |

| Power management |

When the battery power in the machine is low or has not been measured for a long time, it will give sound alarm and automatically shut down. |

| Charging time | 12~24 hours in shutdown state, intelligent charging system, power-off protection after fully charge. |

Product detail pictures:

Related Product Guide:

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for OEM Best megger test electrical Supplier – Substation Temperature Monitoring System – HV Hipot , The product will supply to all over the world, such as: Colombia, USA, Buenos Aires, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.