GDCL-10kA Impulse Current Generator

● Environmental temperature: -10℃ to 40℃

● Related humidity: ≤ 85% RH

● Altitude: ≤ 1000m

● Indoor use

● No conductive dust, no fire or explosive danger, no corrosive metal or insulation gas.

● Power voltage waveform is sine wave, distortion rate <5%

● Earth resistance is no more than 1Ω.

IEC60099-4: 2014 Surge Arresters-Part 4: Metal-oxide surge arresters without gaps for a.c. systems.

GB311.1-1997 Insulation coordination of HV Power transmission and transformation.

IEC 60060-1 High Voltage Testing Technique- General Testing Requirement.

IEC 60060-2 High Voltage Testing Technique- Measurement System.

GB/T16896.1-1997 Digital Recorder of High Voltage Impulse Test.

DLT992-2006 Implementing Rules for Impulse Voltage Measurement.

DL/T613-1997 Technical specifications for imported AC gapless metal oxide arresters.

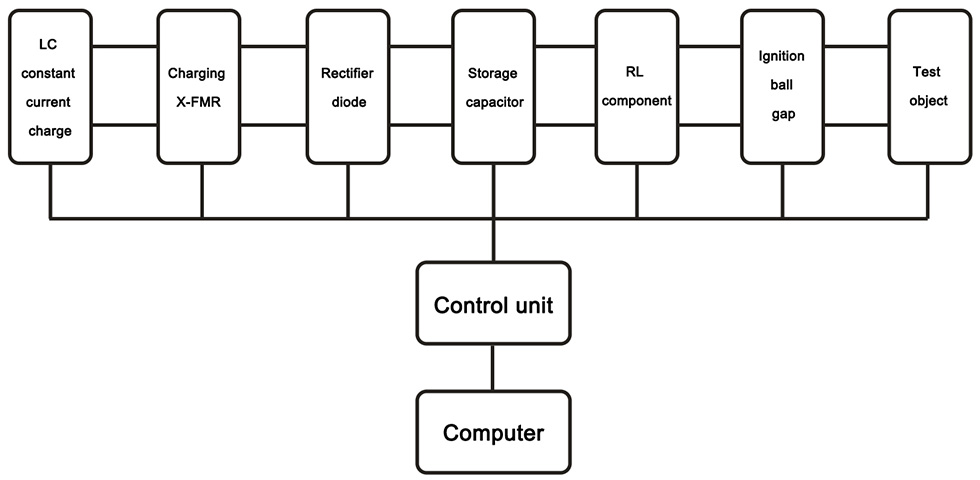

By using LC and RL circuits, the charged capacitor C discharges to nonlinear resistive load through the inductance L and the resistance R to generate the impulse current conforming to the standard requirements.

● Current waveform: 8/20μs

● Rated current: 10kA

● Ignition method: Pneumatic displacement discharge ball distance. Automatic control, manual control.

● Current polarity: positive. Waveform display: current-negative; residual voltage-positive.

● Current measurement: Rogowski coil (0-50kA), accuracy: 1%.

● Residual voltage measurement: resistance voltage divider (0-100kV), accuracy: 1%

● Overall measurement accuracy: 3%

● Waveform display: Oscilloscope (Tektronix) and PC.

● The oscilloscope and capacitor charging voltage are set on PC with one key.

● Data storage: on PC. Measurement data and waveform are collected by oscilloscope, and automatically transmitted to PC via USB port, and saved as Excel format in preset folder on the computer hard disk.

● Safety protection: over-voltage, over-current, access control linkage, emergency stop, automatic grounding. Equipped with manual grounding bar: the operation staff must discharge with the grounding bar before contacting the generator body, replacing waveform resistor, replacing test object, repairing, etc., and connect the grounding bar to the HV end of the body.

● Ground resistance: ≤1Ω

● Power supply: 220V±10%, 50Hz; capacity 10kVA

Charging unit

1) Charging method: half wave rectification with constant current in LC circuit at transformer primary side. Primary side has short-circuit/over-load protection.

2) High-voltage rectifier diode: reverse voltage 150kV, Max. Average current 0.2A.

3) Transformer primary voltage 220V, secondary voltage 50kV, rated capacity 10kVA.

4) Charging protective resistor: the enameled resistance wire is inductively dense wound on the insulation tube.

5) Constant current charging device: within 10~100% rated charging voltage, adjustable accuracy of charging voltage is 1%, and actual charging accuracy is better than 1%.

6) Voltage monitoring of capacitor: DC resistance voltage divider uses glass uranium resistance and metal film resistance. The voltage signal of the low-voltage arm is transmitted to the measuring system by shielded cable.

Discharge Unit

1) Auto grounding device: when the test is stopped or any other reason causes the access control to open, the high voltage terminal can be automatically grounded by the protective resistor and quickly discharged.

2) The discharging device adopts the pneumatic solenoid valve separation and grounding mechanism, which has compact structure, strong transmission stability and reliable action.

3) The discharge sphere is made of graphite with strong heat resistance and resistance to large current.

Generator

1) Four energy storage capacitors are divided into two groups and placed on the insulated chassis bracket respectively. Wave-front inductance and the wave-end resistance are respectively fixed in the corresponding positions, which are simple, clear, firm and reliable.

2) Clamping device of test object is strengthened by pneumatic pusher.

3) The ignition device adopts pneumatic components to move the isolated ball distance and discharge through the ball gap, which is stable and reliable.

1) Residual voltage: resistance voltage divider, non-inductive resistance, high precision, Max. voltage is 30kV, equipped with 1pc 75Ω measuring cable, 5meters.

2) Current: Using Rogowski coil with maximum current of 100kA and 1pc 75Ω measuring cable, 5meters.

3) Oscilloscope: Using Tektronix DPO2002B, sampling rate of 1GS/s, 100MHz broadband, two channels.

4) Software: equipped with ICG impulse current measurement system, with data and waveform reading/storage and calculation functions.

Control Unit

Control Unit

1) Table type Workbench enables operation staff to operate while sitting, more convenient.

2) The cabinet is equipped with movable casters and fixed support, which can facilitate movement and position fixing.

3) Optimal design of control system, user-friendly interface, only 3 buttons (charge, discharge, ignition) and a band switch (four waveform conversion), high reliability, simple structure, easy to operate, easy to maintain.

4) Oscilloscope setting is controlled by computer and completed with one key, which avoids complicated manual operation (oscilloscope has many functions, which is difficult for non-professionals to control).

5) Capacitor charging voltage is controlled by computer, with clear interface and simple operation.

6) The oscilloscope establishes a communication connection with the computer, the measurement data and waveform are automatically saved in the computer, and the Excel document is automatically generated.

7) Power supply of control system: isolated by transformer and filter.

8) Protection: over-voltage, over-current, access control linkage, emergency stop, automatic grounding, etc.

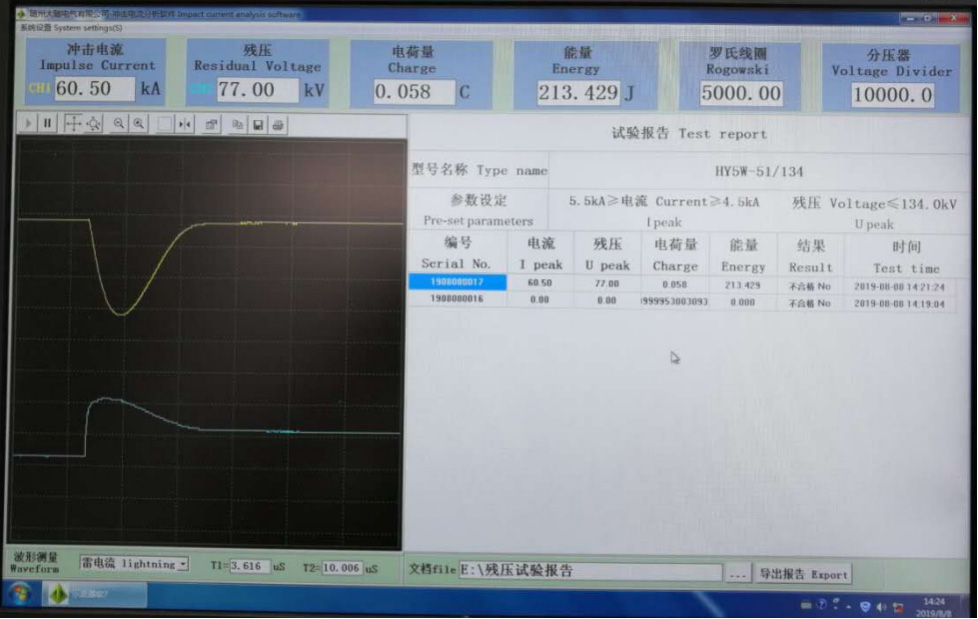

The analysis software is developed for impulse current test can automatically read waveform and data through communication with oscilloscope and evaluate waveform according to the measurement method of IEC1083-2 standard. Current peak, voltage peak, wave-front time and wave-end time are calculated automatically and displayed on the computer screen together with test waveform.

Data and waveform can be saved automatically and continuously (random shooting at the test site)